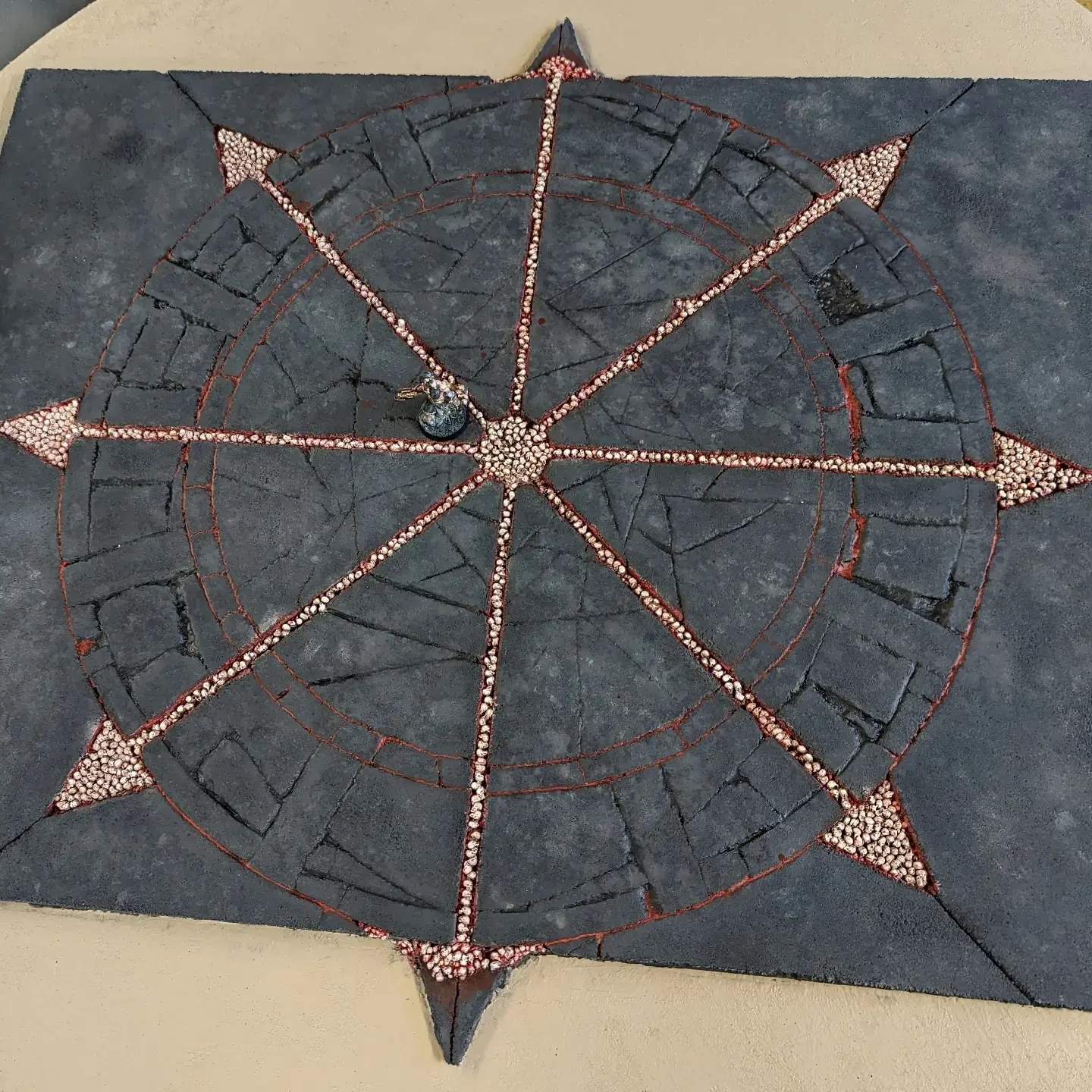

I wrote about inspiration and design in part 1 and laying the mosaic in part 2. Now for my favorite part: skull trenches!

Proof of concept

I had a healthy collection of little plastic skulls, but not enough to fill the chaos star. I needed to make more.

I decided to try push molding and casting. I had applied this technique to reproduce interesting details before, but never on this scale. I started with a proof of concept piece.

I laid a master pattern onto a blob of blu-tac and put the kettle on.

I formed a mold using thermoplastic, which softens dramatically when submerged in near-boiling water, then hardens within minutes as it cools to room temperature.

Green Stuff World markets this as Blue Stuff, but I got mine from Amazon under the name Hinodewashi Oyumaru.

I peeled the cooled mold from the pattern, then pressed Milliput into the mold. Five hours later I had a replica skull pile.

I built a macabre little banner for our kick-off Nightwatch game. Satisfactory result!

Skull factory

Filling the skull trenches required additional problem solving. Blu-tac sticks to the mold too much, and the thermoplastic would damage the edges of the cork if I formed the mold directly on the board.

Eventually I used PVA glue to stick skulls to trench-width strips of foam. It worked, but I sense room for improvement.

Once the molds were formed, I reused them to cast enough skulls to fill all the trenches. This type of work, doing something for ten minutes every five hours, is great if you can be home during lunchtime.

Casting skulls for the arrowheads and center pit demanded still more adaptation. I could sink tedious hours into building a pattern on foam for each arrowhead, or try reusing one or two molds and fill any resulting gaps somehow.

I didn’t like either approach, so I decided to mold the skulls directly on the board, over a baking parchment barrier. The parchment protected the cork edges from moisture and clingy thermoplastic.

That approach produced great results. I didn’t have enough thermoplastic to mold all six arrowheads at once, but I could reuse what I had. I repeated a process like this:

- Toss the last mold into hot water

- Press parchment into the arrowhead

- Pour a cup o’ skulls in and shake the board until it looks right

- Press the molten thermoplastic onto the skulls in the arrowhead

- Pick the skulls out of the cooled mold and put them back in the cup

- Cast the shape with Milliput

If I ever repeat this project, I may do the trenches this way too.

Caulk and balls

I wanted trenches absolutely brimming with skulls, and realized during dry-fitting that I would need some kind of filler to accomplish that. Fortunately, Mel the Terrain Tutor provided me an idea with perfect timing.

I mixed up a paste of painter’s caulk and 2-3mm expanded polystyrene balls. A liter of those balls set me back about $10 on Amazon.

This goop is typically used as bulk filler with finishing texture applied afterward, but left as-is it approximates tiny craniums*. It also serves as an adhesive, perfect for my needs!

A satisfying milestone

Applying the last of the skulls to the board felt amazing. By this point I was coasting on momentum.

Part 4 will examine final surface finishing and painting. Meanwhile, is there a project you might use these methods for?

Your comment sustains me